Döktaş Dökümcülük Tic. ve San. A.Ş.

Industry :

Chassis (aluminium components), Powertrain (aluminium components), Engine (aluminium components), R&D, Design, Engineering, Aluminum Casting, Heat Treatment, Mold,Painting, Machining,Aluminium Alloy WheelsINTRODUCTION ABOUT THE COMPANY

Döktaş is the leader company of the Turkish foundry industry, manufactures iron and aluminum cast components for automotive, heavy trucks, agricultural machinery, construction machinery, and machine-building industries.

Orhangazi business unit produces rough and machined iron castings. Aluminum castings together with aluminum wheels are manufactured in Manisa Plants.

MISSION

To remain our leadership position as a cast iron, light-alloy aluminum casting, and wheel supplier.

VISION

Our vision is to be a preferred and reliable leading company as being iron casting, light alloyed aluminum casting, and wheel products supplier. We aim to preserve and strengthen our position in casting business.

Aluminium Business Unit:

PRODUCTS:

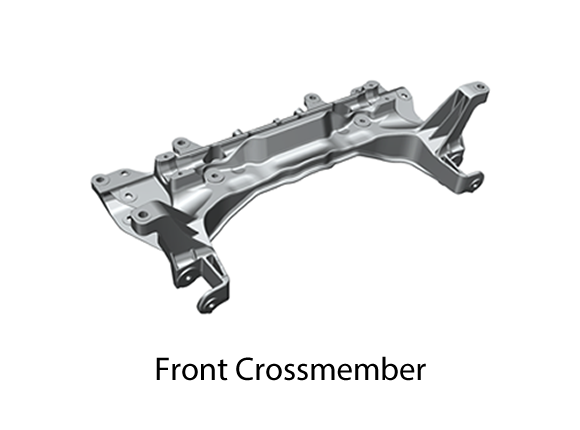

Chasis Parts: Control Arm, Rear Cross Member, Steering Box Rocker, Front Cross Member, Steering Housing

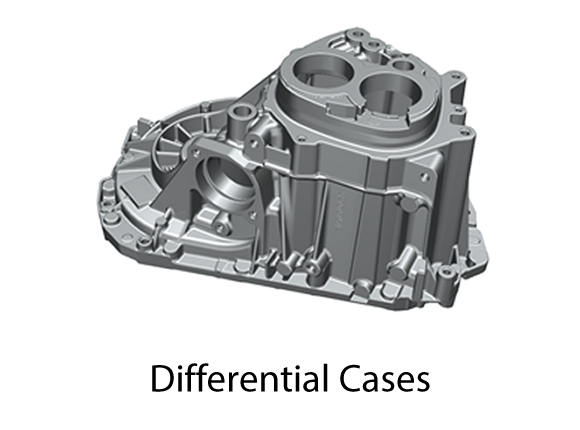

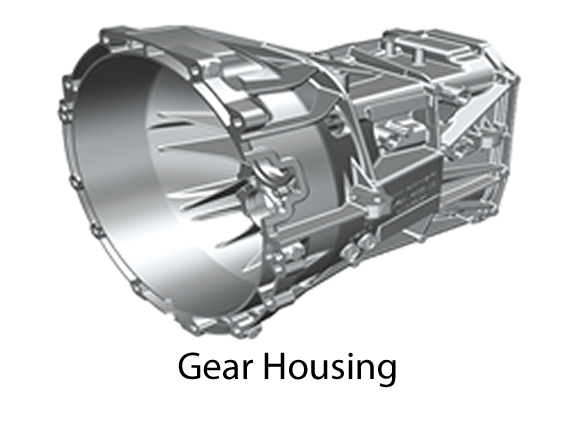

Powertrain Parts: Front Drive Carrier, Clutch Housing, Transmission Housing.

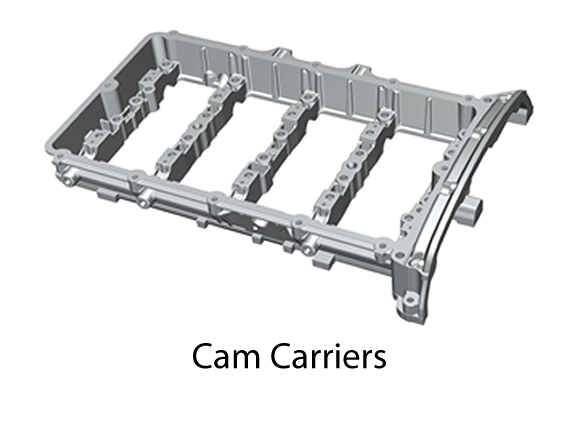

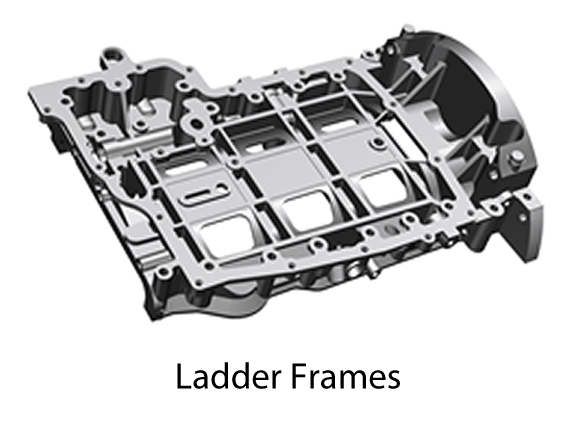

Engine Parts: Cam Carrier, Ladder Frame, Cylinder Head

SOLUTIONS:

Aluminium casting components (with or without machining) for automotive

SERVICES:

Tooling design, product-process development, prototyping

Wheels Business Unit:

PRODUCTS:

Aluminium Alloy Wheels from size 13” – 22” for automotive OES and aftermarket.

SOLUTIONS:

Wheel design, engineering studies, analysis, tool design.

SERVICES:

Conducting wheel material analysis and fatigue tests.

Aluminum Business Unit:

Melting, casting, x-ray, heat treatment, sand casting, x-ray, machining, and packaging

The maximum production capacity of 15.000 tons/year

Low pressure die casting machines and high pressure die casting machines range from 700 to 3200 tons.

4 to 5 axes horizontal machining center

Wheel Business Unit:

Melting, Foundry, X-Ray, Heat Treatment, Deburring machining line, Paintshop, packaging line.

1.400.000 Aluminium Alloy Wheels per year.

Aluminium Business Unit:

- ISO 9001

- ISO 14001

- IATF 16949

- OHSAS 18001

- ISO 27001:2013

- OHSAS 45001: 2018

Wheel Business Unit:

- ISO 9001:2015

- IATF 16949:2016

- ISO 14001:2015

- ISO 45001:2018

- ISO 27001

Aluminum Business Unit:

- RENAULT

- FORD

- EATON

- AAM

- VOLVO

- GRUNER

- ZF

- ANVIS

- FIAT

- MAGNETI MARELLI

- THYSSENKRUPP

- NEW HOLLAND AGRICULTURE

Wheel Business Unit:

- BORBET

- OZ

- ATU

- DBV

- AD VIMOTION

- GEWE